PTFE Coated Fiberglass Belt

We select advanced imported loom and high-quality imported fiberglass or Kevlar as basic weaving material. By weaving, the material can be made into high-intensity fiberglass mesh. then, the mesh will be coated with excellent PTFE resin and then be made into PTFE coated fiberglass belt.

According to excellent performance, so it is widely used in screen printing industry, textile industry, non woven fabric production, thermal bonding oven, tannery machiney, IR or UV system, paper making, food processing, drying, environmental protection, chemical industry, glass, medicine, electronics, insulation, grinding wheel slice and other fields.

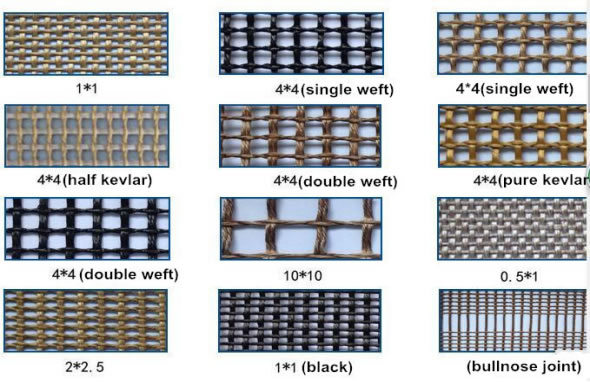

Specification

Grid size

| Model | Material | Mesh size | Thickness | Weight | Temperature resistance | Warp/Weft tensile strength |

| 6001 | Fiberglass | 1x1mm | 0.0197inch | 0.682pound/sq.yard | -94 to 500℉ | 176.9/165.5pound/inch |

| 0.50mm | 370g/m² | -70 to 260℃ | 1550/1450N/5cm | |||

| 6002 | Fiberglass | 2x2mm | 0.0276inch | 0.829pound/sq.yard | -94 to 500℉ | 199.8/176.9pound/inch |

| 0.70mm | 450g/m² | -70-260℃ | 1750/1550N/5cm | |||

| 6004 | Fiberglass | 4x4mm | 0.0394inch | 0.737pound/sq.yard | -94 to 500℉ | 222.6/182.7pound/inch |

| 1.0mm | 400g/m² | -70-260℃ | 1950/1600N/5cm | |||

| 6004B | Fiberglass | 4x4mm | 0.0394inch | 0.829pound/sq.yard | -94 to 500℉ | 222.6/182.7pound/inch |

| 1.0mm | 450g/m² | -70-260℃ | 1950/1600N/5cm | |||

| 6007 | Kevlar+ Fiberglass | 4x4mm | 0.0473inch | 1.106pound/sq.yard | -94 to 500℉ | 376.7/211.2pound/inch |

| 1.2mm | 600g/m² | -70-260℃ | 3300/1850N/5cm | |||

| 6008 | Fiberglass | 4x4mm | 0.0473inch | 1.078pound/sq.yard | -94 to 500℉ | 225.5/211.2pound/inch |

| 1.2mm | 585g/m² | -70-260℃ | 1975/1850N/5cm | |||

| 6009 | Kevlar | 4x4mm | 0.0394inch | 0.848pound/sq.yard | -94 to 500℉ | 399.6/376.7pound/inch |

| 1.0mm | 460g/m² | -70-260℃ | 3500/3300N/5cm | |||

| 6010 | Fiberglass | 10x10mm | 0.0473inch | 0.829pound/sq.yard | -94 to 500℉ | 205.5/171.2pound/inch |

| 1.2mm | 450g/m² | -70-260℃ | 1800/1500N/5cm | |||

| 6015 | Fiberglass | 0.5x1mm | 0.0197inch | 0.774pound/sq.yard | -94 to 500℉ | 176.9/165.5pound/inch |

| 0.5mm | 420g/m² | -70-260℃ | 1550/1450N/5cm | |||

| 6025 | Fiberglass | 2*2.5mm | 0.0355inch | 1.106pound/sq.yard | -94 to 500℉ | 222.6/182.7pound/inch |

| 0.9mm | 600g/m² | -70-260℃ | 1950/1600N/5cm |

Splice type

There are three types of splice, including:

|

Alligator splice, it is a metal fastener, it can be used on both open mesh and closed weave type ptfe belt, belts utilizing alligator can be installed without taking machine apart. It can be used in when belt width is less than 1m. |

|

Fabric pin splice, it is similar to alligator splice but without any metal components, its flatness is the best, it can easily be installed, there is the fastest installation speed and the shortest installation time, it can save your time. |

|

Bull nose splice, it is woven in a way that leaves out a number of rows of weft threads, when folded in this area it creates a loop that can accept a connection pin. Although its flatness is not good as the fabric pin splice, but it is the most commonly used splice. |

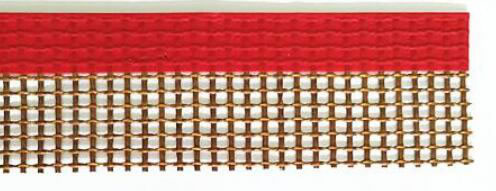

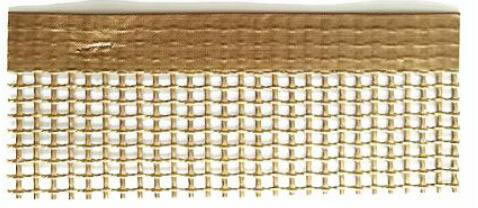

Side band material

There are three types of side band material, including:

PTFE thin film side band, its colour can be white or red or black, with good wearing resistance and long service life.

PTFE fiberglass side band, its colour can be brown or black, if belt contains guides, it will be the best choice.

PTFE kevlar side band, its colour is yellow, with the best wearing resistance and the longest service life.

Belt tracking / guiding types

A guiding system is essential for most of PTFE belts. Guiding may be by external guiding systems or by combining a system in the belt construction, such as metal studs, teflon pins or eyelets. External, electrical or mechanical systems are preferred, since they are suitable for all widths of belts and prolong belt life by preventing edge damage due to incorrect tracking.

Tips for optimizing belt life; Run at low tensions, use only flat rollers, ensure each roller is aligned properly and utilize an automatic guiding system.

|

Guides |

|

Metal Eyelets |

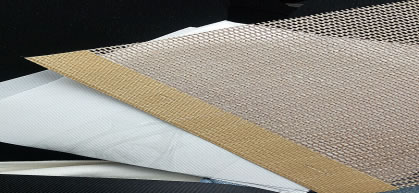

Features

1. High temperature resistance. It can continuously work under -140℃ to 260℃, max resist high temperature is up to 360℃

2. Air permeability. It can avoid wasting heat and improve drying efficiency.

3. Chemical resistance.It can resist all most of chemical medicines.

4. Non-Sticky. It can easily remove all kinds of adhesives such as resin, paint and chemical medicines.

5. Good flex fatigue resistance. It has high tensile strength and excellent flex fatigue resistance. It's also used for small wheels

Application

1. Textile and dyeing: drying for textile printing, dyeing, shrinking, non-woven fabric, and in industry oven.

2. The loose-dryer, offset, UV curing machine, paper oil drying, UV drying, plastic printing drying.

3. High-frequency wave drying, microwave drying, food refrigeration and defrost, baking, packaging heat shrinking.

4.Oiling machine for paper glazing and waxing, plant engineering.

5. Seperating sheet for hardboard production etc.

|

|

| PTFE Coated Fiberglass Belt | PTFE Coated Fiberglass Belt |

|

|

| Teflon Mesh Belt | Teflon Mesh Belt |